- TJ

- shanghai,china

- 15-30days

- 30 units per month

The working principles when the Pharmaceutical Manufacturing High Efficiency Mixer is in operation. Because of the running actions of the mixing tank in multi direction, the now and derision of the various kinds of materials are sped up in the process of mixing.

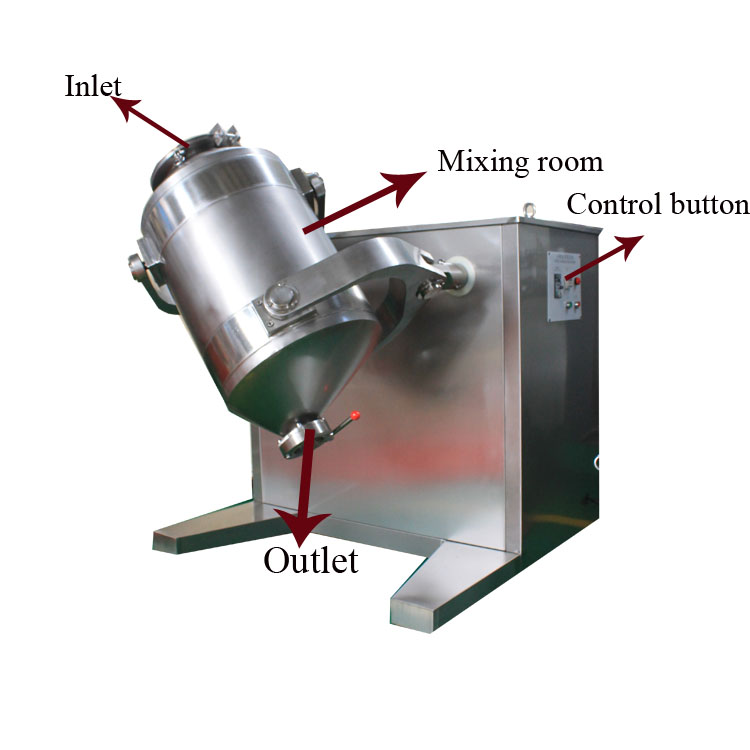

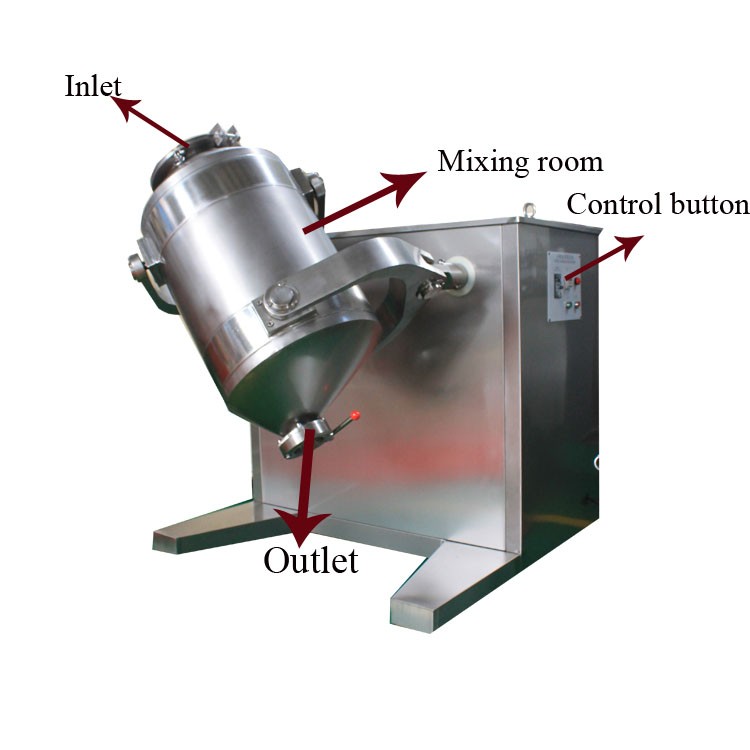

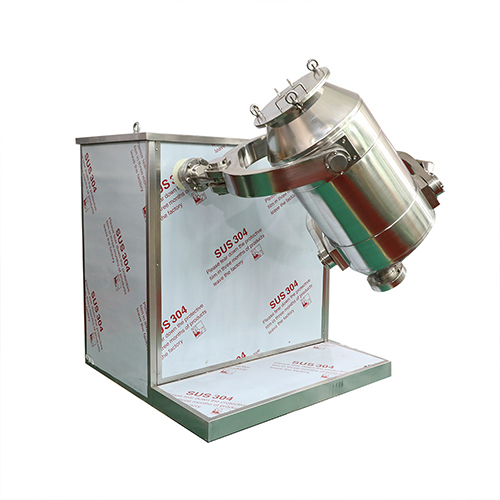

Pharmaceutical Manufacturing High Efficiency Mixer

Pharmaceutical Manufacturing High Efficiency Mixer introduction

At the same time, the phenomenon is avoided that the congregation and segregation of the material in gravity ratio caning due to the centrifugal force in the normal Pharmaceutical Manufacturing High Efficiency Mixer and extremely good effect can be obtained.

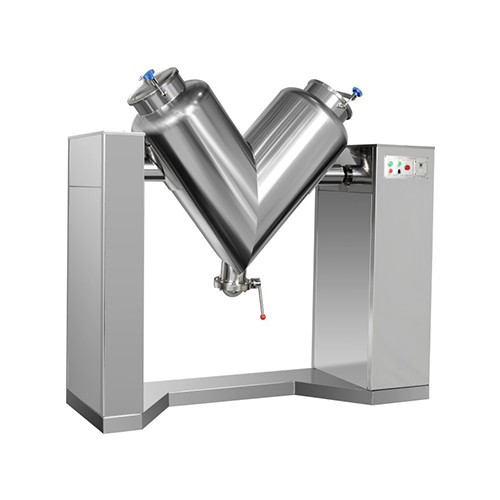

Series Multi directional Movement Mixer consists of the base, driving system. Electric control system, multi-directional, movement mechanism and mixing tank. The Pharmaceutical Manufacturing High Efficiency Mixer tank to be in contact with the materials is made of quality stainless steel, with both inside and outside of the tank mirror polished.

Because the Pharmaceutical Manufacturing High Efficiency Mixer performs a multi directional movement, there are many points of mixing with a good effect of mixing. The uniformity of the mixing iceberg than that of the normal mixer.

The shape of the Pharmaceutical Manufacturing High Efficiency Mixer is reasonably designed with no death corner and both the inside and outside polished. The discharge of materials is free with no accumulation. It is easy to clean.

The materials are mixed in an enclosed state. With no contamination to the working environment and materials.

Pharmaceutical Manufacturing High Efficiency Mixer Technique Parameter

Model | SBH-10 | SBH-50 | SBH-100 | SBH-200 |

Barrel capacity(L) | 10 | 50 | 100 | 200 |

Capacity max(L) | 8 | 40 | 80 | 160 |

Capacity weight(kg) | 5 | 25 | 50 | 100 |

Speed of mine shaft | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) |

Motor power(kw) | 0.55 | 1.1 | 1.5 | 2.2 |

Overall size(mm) | 800*1200*1000 | 1000*1400*1200 | 1200*1700*1500 | 1400*1800*1600 |

Weight (kg) | 200 | 300 | 500 | 800 |

Model | SBH-300 | SBH-400 | SBH-500 | SBH-600 |

Barrel capacity(L) | 300 | 400 | 500 | 600 |

Capacity max(L) | 240 | 320 | 400 | 480 |

Capacity weight(kg) | 150 | 200 | 250 | 300 |

Speed of mine shaft | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) |

Motor power(kw) | 4 | 4 | 5.5 | 5.5 |

Overall size(mm) | 1800*1950*1800 | 1800*2100*1950 | 1900*2000*2100 | 1900*2100*2250 |

Weight (kg) | 1000 | 1200 | 1380 | 1500 |

Model | SBH-800 | SBH-1000 | SBH-1200 | SBH-1500 |

Barrel capacity(L) | 800 | 1000 | 1200 | 1500 |

Capacity max(L) | 640 | 800 | 950 | 1200 |

Capacity weight(kg) | 400 | 500 | 600 | 750 |

Speed of mine shaft | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) | 0-15(r/min) |

Motor power(kw) | 7.5 | 7.5 | 11 | 15 |

Overall size(mm) | 2200*2600*2600 | 2250*2600*2600 | 2400*2800*2800 | 2500*2950*3000 |

Weight (kg) | 2000 | 2500 | 2800 | 3000 |

Pharmaceutical Manufacturing High Efficiency Mixer Main application

This Pharmaceutical Manufacturing High Efficiency Mixer is suitable for mixing dry-powder material of pharmaceutical, chemical and food industries.The Pharmaceutical Manufacturing High Efficiency Mixer models are mainly SBH-10, 50, 100, 200, 300, 400, 500, 600, 800, 1000, 1200, 1500 Three-dimensional Movement Mixer

Pharmaceutical Manufacturing High Efficiency Mixer is used in mixing evenly and quickly between different proportion and fineness of materials.

The working principles when the Pharmaceutical Manufacturing High Efficiency Mixer is in operation. Because of the running actions of the mixing tank in multi direction, the now and derision of the various kinds of materials are sped up in the process of mixing.