- TJ

- shanghai,china

- 10-15days

- 30 units per month

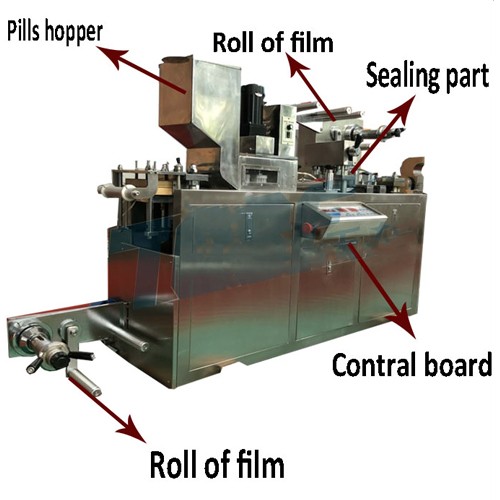

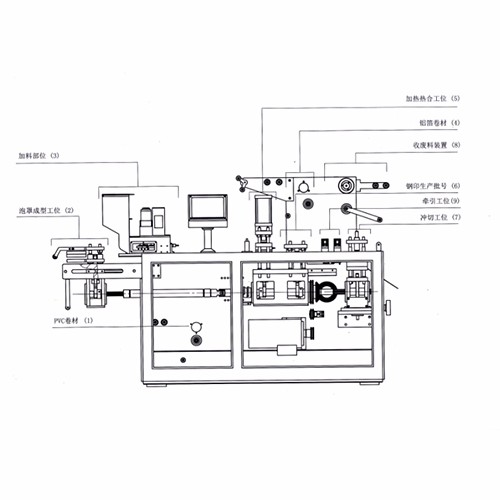

DPP-150 Capsule Blister Packing Machine adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

DPP-150 Capsule Blister Packing Machine

DPP-150 Capsule Blister Packing Machine introduction

The DPP-150 Capsule Blister Packing Machine is suitable for industries of foodstuff, medicine, medical instruments, hardware, electronics and etc for packing.

Imported controlling system is adopted; also it can be equipped with detecting and rejection function device (Omron Sensor) for number of medicines according to the user’s requirement. It adopts imported frequency inverter

DPP-150 Capsule Blister Packing Machine adopts photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

DPP-150 Capsule Blister Packing Machine Configuration list

Item | Name | Spec/model | Brand | Qty |

1 | Traction Cylinder | SSA φ32×15 | Kaogeer | 2 |

2 | Main Motor | YS1500W-4R | ZhejiangTaibang | 1 |

3 | Forming heating plate | 170×130×20 | Zhejiang hongxing | 2 |

4 | Heating sealing plate | 158×110×20 | Zhejiang hongxing | 1 |

5 | Frequency inverter | DVA-3S0015G | 1 | |

6 | Feeding motor | 70-CK-25-K | 1 | |

7 | Waste material collection motor | 4GN-15-K | 2 | |

8 | Thermocouple | TES-2M | Tes Taiwan | 2 |

9 | Air circuit breaker | C65N-25A/3P | Schneider | 1 |

10 | Air circuit breaker | C65N-10A/1P | Schneider | 2 |

11 | Air circuit breaker | C65N-6A/1P | Schneider | 1 |

12 | Relay | HRS4H-S | HKE | 5 |

13 | PC controlling panel | / | Shanghai tianjiu | 1 |

14 | Solid relay | SSR-40DA | Fotek Taiwan | 2 |

15 | Controlling Transformer | JBK3-63 | Zhejiang Chint | 1 |

16 | Electromagnetic valve | SG4V210-08 | AirTAC | 3 |

17 | Emergency button | XB2-BS542 | Schneider | 1 |

18 | Photoelectrical sensor | J12-A4JK | BDL | 3 |

DPP-150 Capsule Blister Packing Machine Technical specifications

Punches frequency | 10-35times/min |

Production capacity | 1200-4200plates/hour( two plates one time) |

Max. forming area and depth | 130x100(standard thickness≤15mm) Max. depth 26mm |

Stroke range | 50-120mm( can be designed as per user’s required) |

Standard plate size | 80x57mm ( can be designed as per user’s required) |

Clean compressed air | 0.4∽0.6Mpa |

Air compressed capacity | ≥0.3m3/min |

Total power supply | 380V 50HZ 3.8kw |

Main power | 1.5KW |

PVC hard film | (0.15∽0.5)×150mm |

PTP Aluminum film | (0.02∽0.035)×150mm |

Dialysis paper | (0.02∽0.035)×150mm |

Mould cooling | Tap water or recycling water |

Overall dimension | 2315×635×1405mm(L×W×H) |

Net Weight | 820KG |

Gross Weight | 890KG |

Overall Dimension | 2500×800×1780mm(L×W×H) |

Noise | <75dB |

DPP-150 Capsule Blister Packing Machine Features

DPP-150 Capsule Blister Packing Machine adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

DPP-150 Capsule Blister Packing Machine can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.